Final project meeting

At the beginning of January, the project team met for the final meeting in Espoo…

read more

Walki is an international paper producer and organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia.

The production facilities are located in Finland, Germany, the Netherlands, Belgium, Poland, the UK, Russia and China. To best cater to the global customers, Walki aim to continue investing in state-of-the-art production facilities and promoting innovation and exceptional service worldwide. Walki’s annual net sales was year 2019 approx. 400 million Euros and the company has a workforce of about 1000 people.

Walki believe in a sustainable and circular tomorrow with a mission to accelerate the world’s transition into a zero waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials. Specialist barrier coated and laminated materials are used to protect packed products, reduce waste and improve functionality of the finished pack, for example, by using easy open tear-strip features. For the paper industry Walki produce specialist products such as wrappers for paper industry reels, including reel end discs, and printed wrappers for A4 and A3 cut size and folio reams.

Walki will provide mulch paper as benchmark materials, but also as substrate for further optimization with hybrid polymers. In the end of the project, the production of mulch covers, including the impregnation with hybrid polymers on pilot scale is planned (300 mm width; approx. 60 m/min). The core competence of coating and impregnation of paper-based materials on pilot scale will be contributed within this project. Also the nanocellulose-based degradable films will be tested on pilot line and Walki will evaluate the films in different food packaging application and will test the mulch films.

To reach the targeted goals, the project partners work hand in hand and to make sure that the results can be transferred into the production process after the end of the project, and an intensive exchange between the partners and countries is achieved. The project work is portioned in various technical activities, which, in addition to the important aspects such as reporting, dissemination and explications represent the center of the project.

At the beginning of January, the project team met for the final meeting in Espoo…

read more

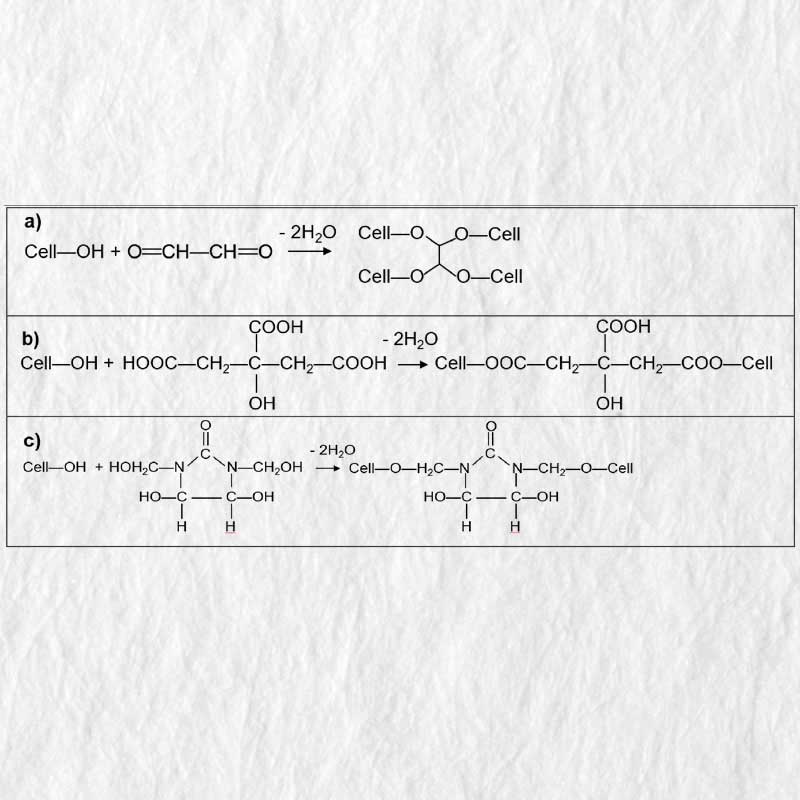

VTT made a comparative study on the Effects of Chemical Crosslinking Agents on NBSK Handsheet.…

read more

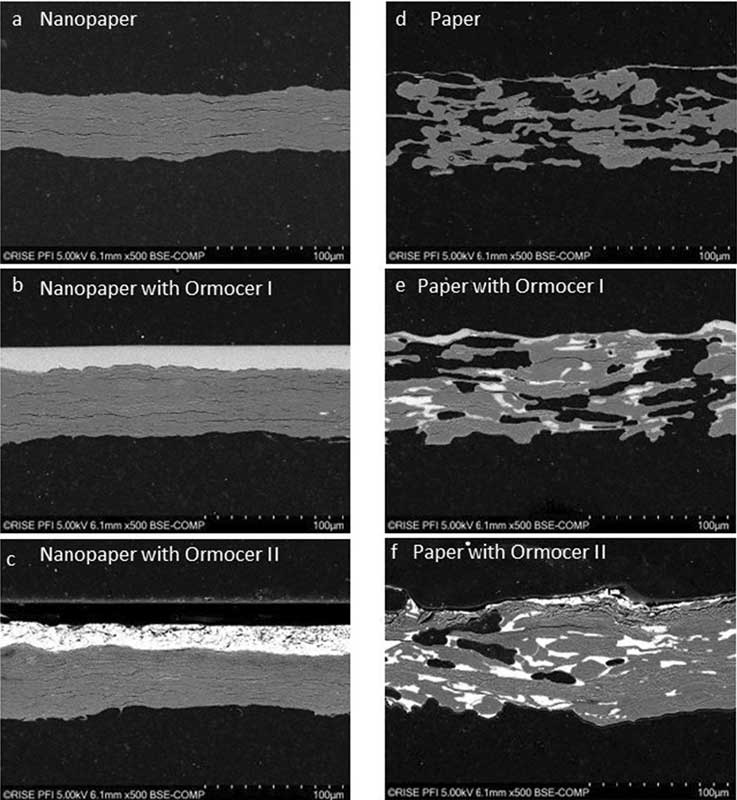

The RISE PFI project team, together with Fraunhofer ISC and VTT, has published an article…

read more